- Anúncios -

O que significa assume?

O que significa assume? A palavra "assume" é uma expressão de origem latina que significa tomar a responsabilidade por algo ou alguém. É um termo bastante utilizado tanto na vida pessoal quanto profissional, indicando a aceitação de um compromisso ou posição. Entrar em ação e assumir as rédeas em determinada situação é um ato de coragem e assertividade.

O que significa error?

O que significa error? Uma palavra que nos desperta incertezas, frustrações e até medos. Mas, ao mesmo tempo, é um lembrete constante de nossa humanidade e capacidade de aprendizado. O error nos leva a questionar, a experimentar, a crescer. É um convite para abraçar a imperfeição e encontrar caminhos inesperados. Afinal, é nos erros que muitas vezes descobrimos os acertos…

O que significa set?

Você já se perguntou o que significa a palavra "set"? Essa pequena palavra em inglês pode ter diferentes significados em diferentes contextos. Vamos explorar suas diversas interpretações e desvendar esse mistério linguístico.

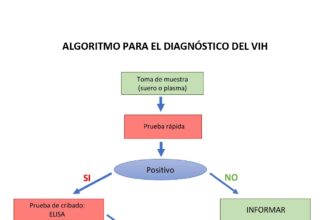

Medicina

O que significa constipação intestinal ou diarreia crônica?

Você já se perguntou o que significa a constipação intestinal ou a…

Create an Amazing Newspaper

Siga-nos

O que significa cálculo?

Cálculo, um termo que provoca curiosidade e talvez até um certo temor…

O que significa escaleno?

Escaleno, uma palavra que encerra mistério e equilíbrio. Entre os triângulos, este…

O que significa aproximação na matemática?

A aproximação na matemática é uma poderosa ferramenta que nos permite obter…

O que significa arco na matemática?

Na matemática, o arco é um elemento fundamental que nos leva a…

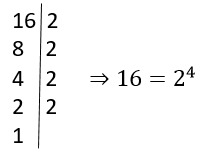

O que significa radiciação?

A radiciação é como um delicado desvendar, um mergulho profundo em busca…

O que significa geometria na matemática?

Geometria, uma palavra que desperta curiosidade e desafia a imaginação. Na matemática,…

O que significa equações irracionais?

Você já se perguntou o real significado das equações irracionais? Elas são…

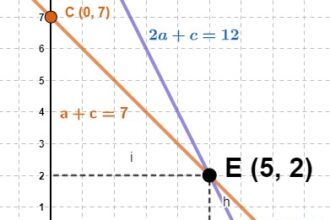

O que significa algoritmo na matemática?

Algoritmo na matemática é como uma incrível coreografia numérica, uma dança entre…

Create an Amazing Newspaper

Conteúdo patrocinado

O que significa capitalismo?

O que significa capitalismo? É um conceito que se desdobra em um verdadeiro oceano de interpretações e debates. Desde sua origem na Revolução Industrial até os dias atuais, o capitalismo abrange os pilares da propriedade privada, da livre iniciativa e do mercado competitivo. Mas, será que esse sistema econômico tem se mostrado eficiente e sustentável para todos? Exploraremos essas questões e muito mais neste artigo, mergulhando nas profundezas desse complexo sistema que molda nossa sociedade contemporânea.

O que significa CEP?

O CEP, ou Código de Endereçamento Postal, é uma seqüência numérica utilizada pelos Correios para facilitar a distribuição de correspondências e encomendas. Cada CEP corresponde a uma área específica, permitindo…

Top Autores

Stay Up to Date

Subscribe to our newsletter to get our newest articles instantly!