- Anúncios -

O que significa gun?

O significado da palavra "gun" pode ser ambíguo e carregado de diferentes conotações. Para alguns, remete a uma arma de fogo, símbolo de poder e violência. Mas também pode representar liberdade, como nas mãos de um caçador solitário em busca de sustento. A verdadeira interpretação de "gun" depende do ponto de vista de quem a observa, revelando-se tanto um objeto…

O que significa investigation?

Investigation, ou investigação, é um termo que desperta curiosidade e mistério. É um processo meticuloso de busca por informações, provas e respostas para desvendar enigmas e esclarecer fatos obscuros. Seja na polícia, na ciência ou até mesmo nas obras literárias, a investigação é como um fio condutor que nos leva a desvendar os segredos ocultos da vida.

O que significa efficient?

O termo "eficiente" é frequentemente usado em diversos contextos, mas você já parou para pensar no seu real significado? Ser eficiente significa realizar uma tarefa de forma otimizada, utilizando recursos adequados e alcançando resultados satisfatórios. Portanto, a eficiência é uma qualidade desejada em diferentes áreas da vida, desde o trabalho até a administração do tempo. Entender o que significa ser…

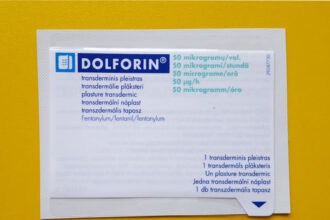

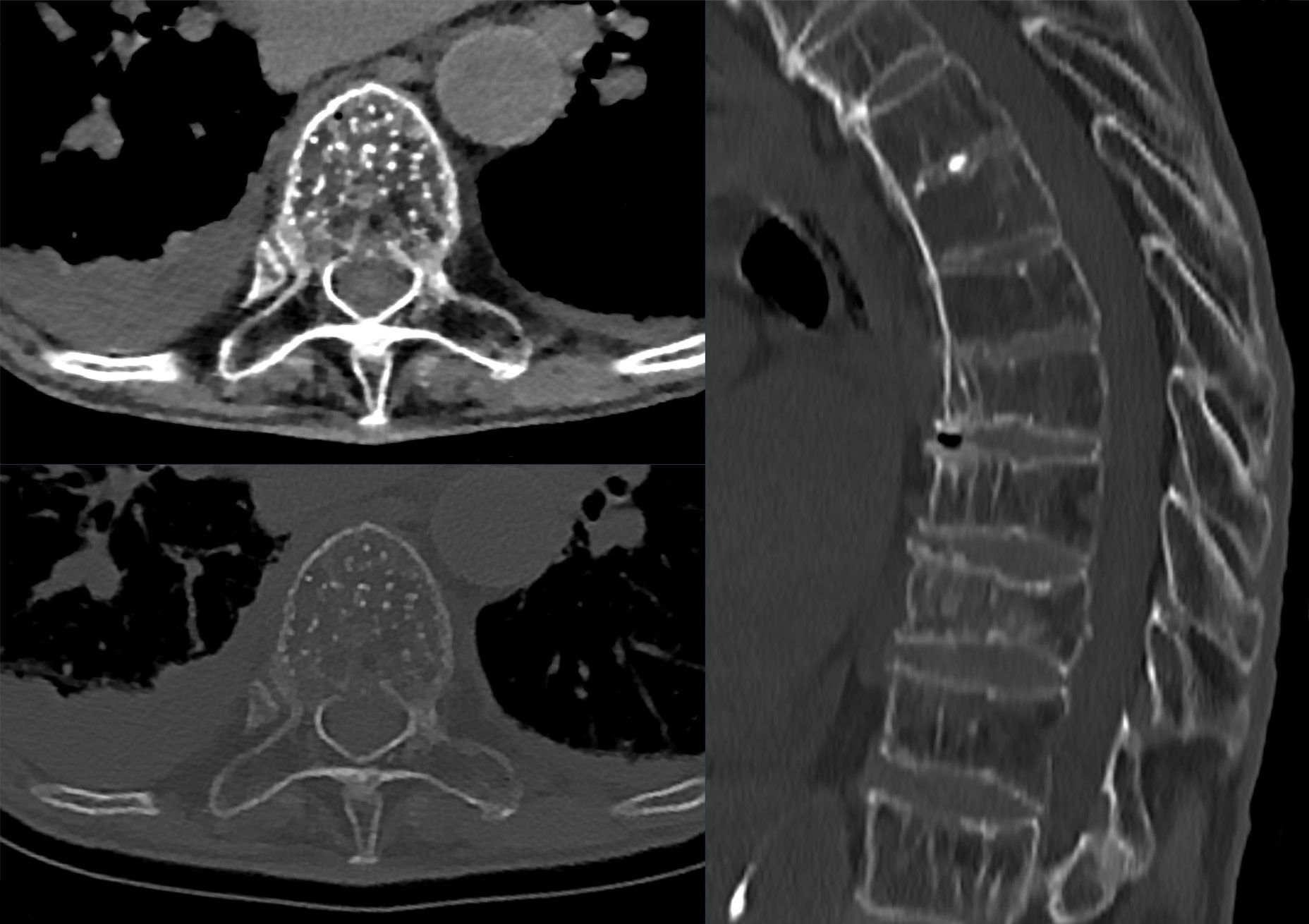

Medicina

O que significa leucemia?

A leucemia é uma doença que se esconde nas sombras, surpreendendo e…

Create an Amazing Newspaper

Siga-nos

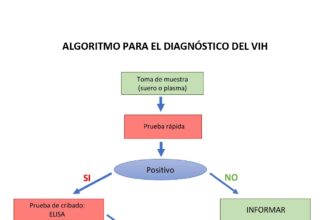

O que significa algoritmo na matemática?

Algoritmo na matemática é como uma incrível coreografia numérica, uma dança entre…

O que significa assíntota na matemática?

As assíntotas são como linhas invisíveis que atraem ou afastam uma curva,…

O que significa integral na matemática?

Você já se perguntou o que realmente significa "integral" na matemática? É…

O que significa escalar na matemática?

Você já se perguntou o que significa escalar na matemática? Bem, imagine-se…

O que significa equações racionais?

Você já se perguntou o que significa equações racionais? Bem, essas equações…

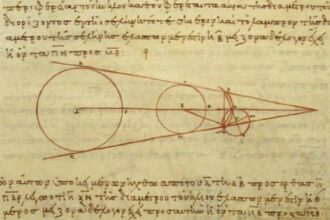

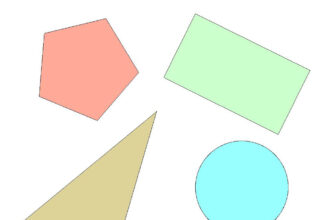

O que significa geometria?

Geometria, a palavra que une formas, linhas e figuras num mundo de…

O que significa equação diferencial na matemática?

Resolver equações diferenciais pode ser desafiador para muitos estudantes de matemática, mas…

O que significa determinante na matemática?

O que significa determinante na matemática? O determinante é uma medida especial…

Create an Amazing Newspaper

Conteúdo patrocinado

O que significa capitalismo?

O que significa capitalismo? É um conceito que se desdobra em um verdadeiro oceano de interpretações e debates. Desde sua origem na Revolução Industrial até os dias atuais, o capitalismo abrange os pilares da propriedade privada, da livre iniciativa e do mercado competitivo. Mas, será que esse sistema econômico tem se mostrado eficiente e sustentável para todos? Exploraremos essas questões e muito mais neste artigo, mergulhando nas profundezas desse complexo sistema que molda nossa sociedade contemporânea.

O que significa IOF?

Se você já teve a curiosidade de saber o que significa IOF, vamos esclarecer esse mistério. IOF é a sigla para Imposto sobre Operações Financeiras. Pode parecer um termo complicado,…

Top Autores

Stay Up to Date

Subscribe to our newsletter to get our newest articles instantly!